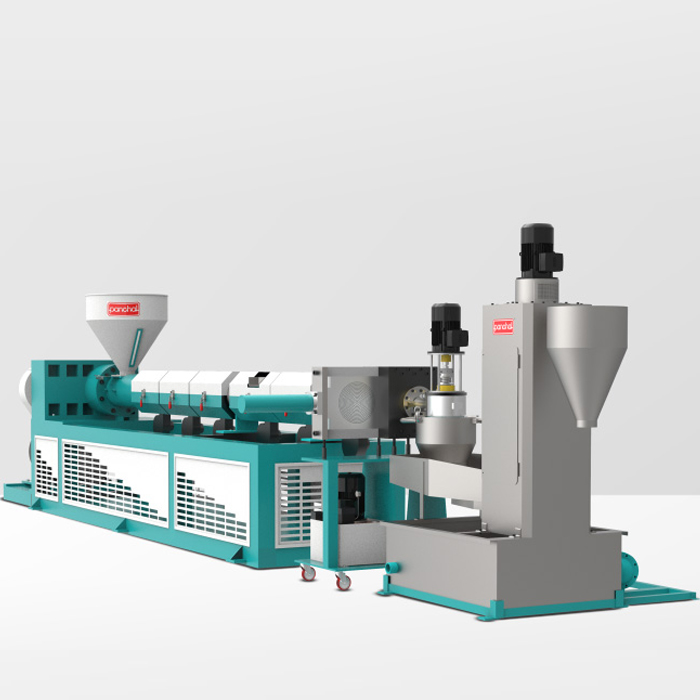

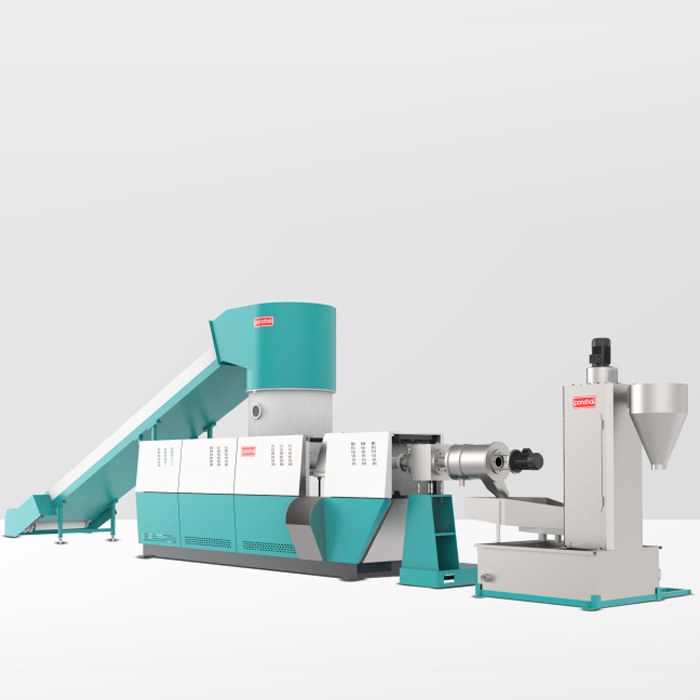

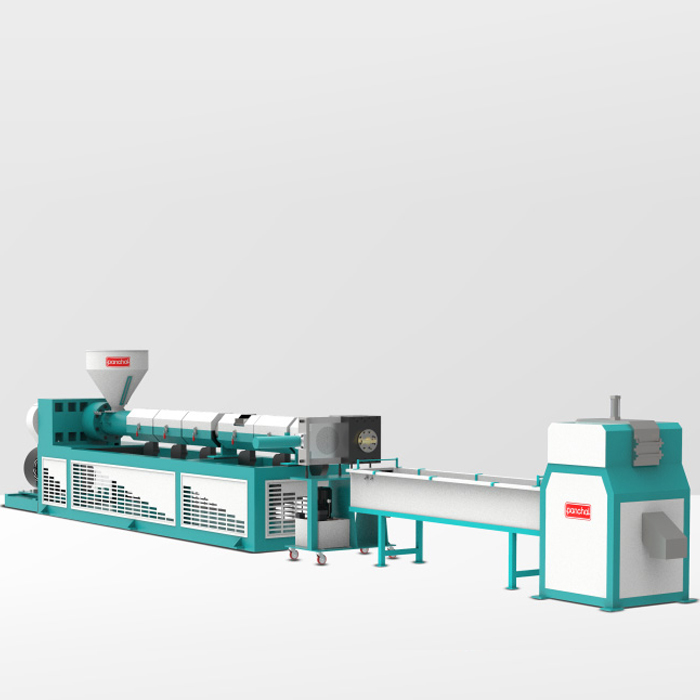

Extruder Edge Trim Recycling

The new Edge-Trim has been designed specifically for use with blown film (multi-layer or mono-layer) to provide small, energy-efficient, non-obstructive recycling of edge trim. Its compact and “open” construction allows for low maintenance, non-operator-dependent, and online operation. AC vector and direct-drive technology keep energy consumption down. Plugs and sockets allow for routine maintenance to be carried out by the operator without the need to wait for dedicated maintenance personnel. An air pelletizing system is used for quick and easy access for cleaning while eliminating the problems associated with water-cooled systems.

Features & Applications

A screw design guarantees gentle melting and produces pellets with minimum degradation.

The minimal loss of physical characteristics allows one to use repelletized scrap at full value to virgin resin in many products.

The ET Series can be fully integrated in a film production plant. This ensures safe and cost-effective inline operation.

A high degree of process stability minimizes the influence of the operating personnel on pellet quality.

Simple access to wear parts reduces scheduled downtime to a minimum.

Robust design, high-grade materials and top quality manufacturing in combination with the finest possible controls and proven electronics, guarantee a long service life.

Due to the excellent output rate in combination with low operating and energy costs the machine typically offers an extremely short payback period. We are pleased to calculate both your recycling operational costs per kg [lbs] and the payback period.

Technical Data

| Model | PPM-50ET |

|---|---|

| Screw Diameter (mm) | 50 |

| Main Motor (HP) | 15 |

| Die-Face Drive (HP) | 1 |

| Cooling Blower (HP) | 2 |

| Production (kg./Hr.) | 15-20 |