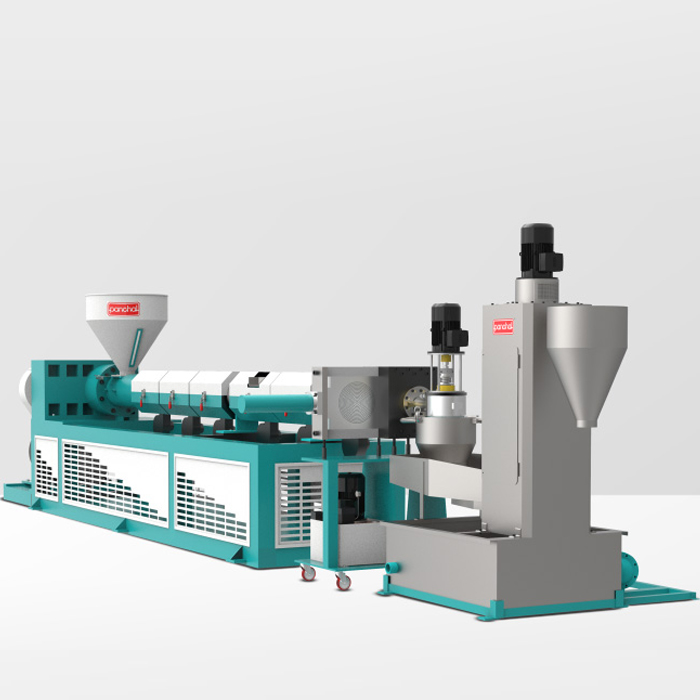

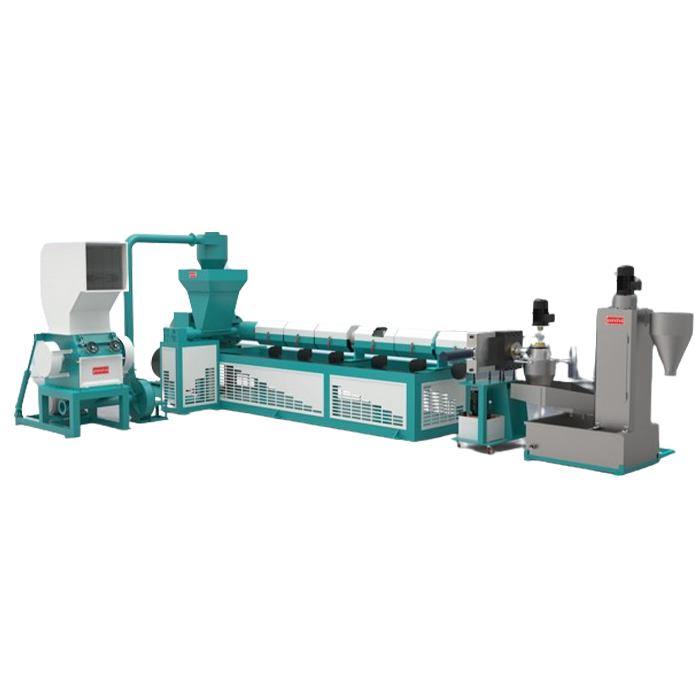

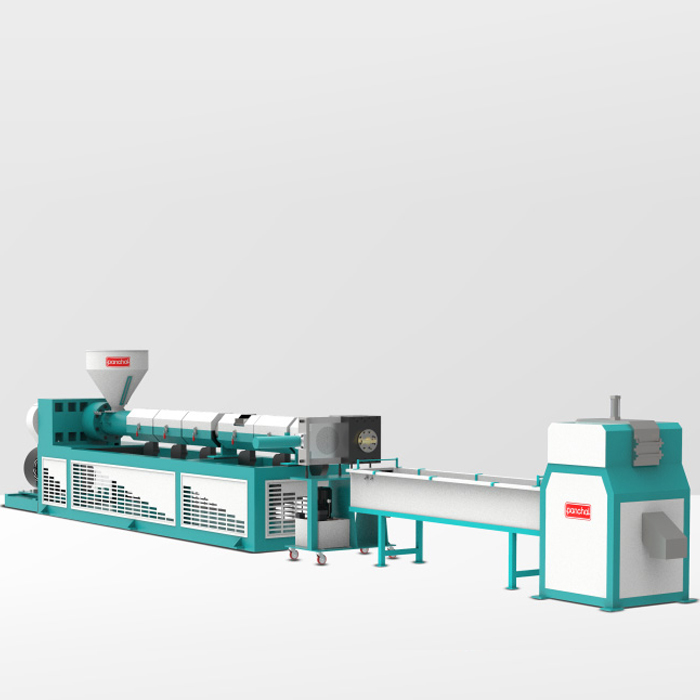

Extruder Mother Baby SP

The Panchal Double Stage Extruder is a versatile machine that can be used for recycling a variety of plastic materials, including those that are highly printed or have high gas formation during reprocessing. The machine has two stages, with the first stage having a longer L/D (length to diameter) ratio than the second stage. This allows the first stage to melt the plastic more efficiently and remove any air bubbles or contaminants. The molten plastic is then transferred to the second stage, where it is further processed and extruded into granules.

The Panchal Double Stage Extruder is a reliable and efficient machine that can be used for a variety of plastic recycling applications. It is ideal for use in manufacturing, packaging, and automotive industries.

Features & Applications

Mother Baby so called Double Stage Extruder is widely used for processing waste which is highly printed or washed material which generate high gas formation during reprocess

Extruder Screw design for Highly degassing of the filtered molten polymer

2 times filter in 2 different filter mesh size

2 time degassing, one in mother extruder degassing port and another in exit of mother extruder to baby extrudre feeding.

Higher homogenisation efficiency downstream of filtration and upstream of degassing enhances the subsequent degassing performance and improves the characteristics of the melt

Technical Data

| Model | PPM-90EMB-SP |

|---|---|

| First Extruder | |

| Production (KG/HR.) | 100-160 |

| Screw Diameter (mm) | 90 |

| L/D Ratio | 35:1 |

| Heating Load (kW) | 30 |

| Main Motor (HP) | 30 |

| Screen Changer (mm) | 150 |

| Second Extruder | |

| Screw Diameter (mm) | 90 |

| L/D Ratio | 10:1 |

| Heating Load (kW) | 7 |

| Main Motor (kW) | 7.5 |

| Palletizer (kW) | 1.5 |