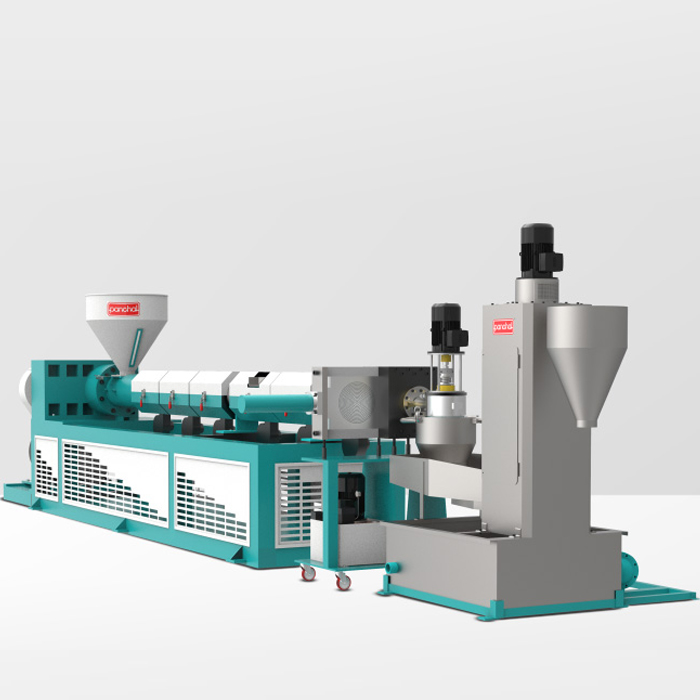

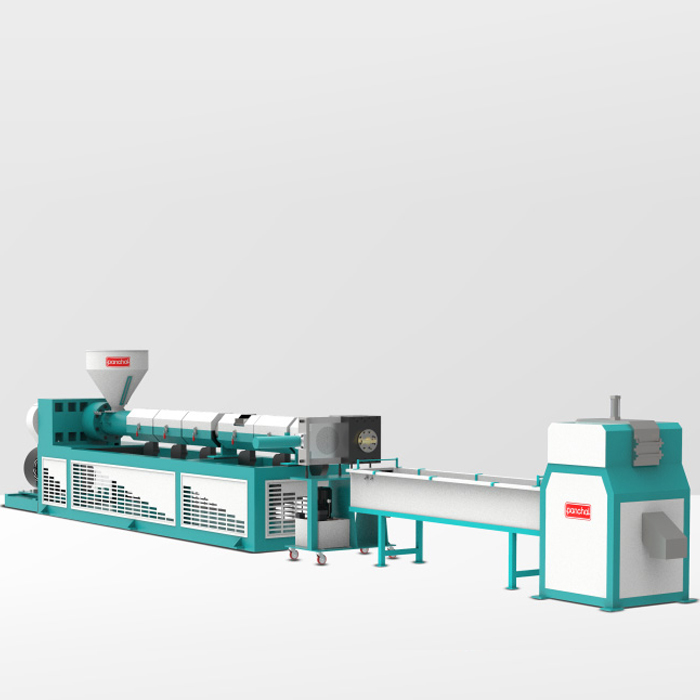

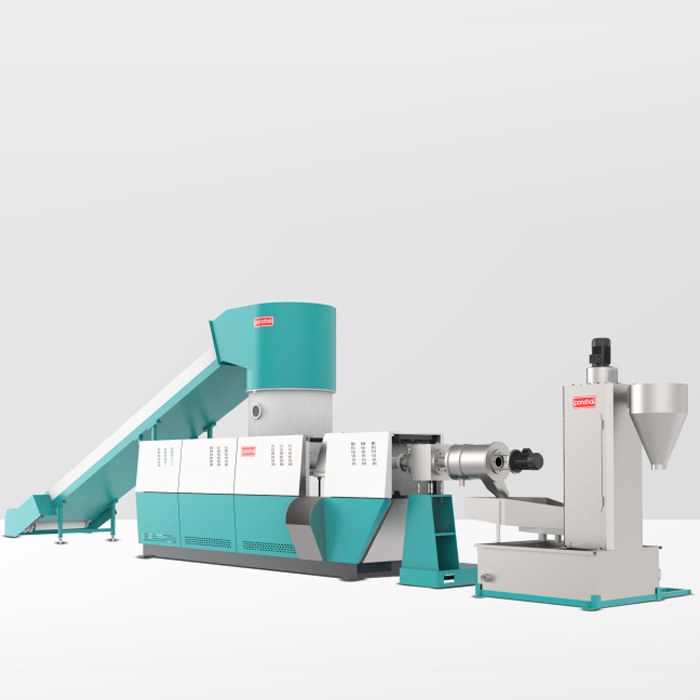

Extruder With Die Face Water Ring PPM 90E-DFW

When considering the acquisition of an extruder machine, one crucial factor to weigh is the cost. This financial aspect can significantly impact your budget and the overall feasibility of your plastic recycling and compounding operations. Our commitment to offering highly competitive prices sets us apart in the industry.

The extruder machine itself is a versatile solution for efficiently processing a wide range of plastic materials, from LDPE and HDPE to HM, ABS, PS, and more. Its adaptability makes it an invaluable asset across diverse applications, including plastic recycling, compounding, and plastic machinery.

Moreover, our innovative die-face cooling system, which utilizes high-pressure water jets, ensures that plastic materials do not overheat and adhere to the die. This results in a cleaner, more uniform product, streamlining plastic material processing while keeping costs in check.

Features & Applications

Explore the advantages of our extruder machine lineup, where quality meets affordability. Make an informed decision and elevate your plastic recycling and compounding endeavors.

A screw design guarantees gentle melting and produces pellets with minimum degradation.

The minimal loss of physical characteristics allows one to use repelletized scrap at full value to virgin resin in many products.

A high degree of process stability minimizes the influence of the operating personnel on pellet quality. Simple access to wear parts reduces scheduled downtime to a minimum.

Robust design, high-grade materials and top quality manufacturing in combination with the finest possible controls and proven electronics, guarantee a long service life.

Due to the excellent output rate in combination with low operating and energy costs the machine typically offers an extremely short payback period.

We are pleased to calculate both your recycling operational costs per kg [lbs] and the payback period.

Technical Data

| Model | PPM 90EX-SP |

|---|---|

| Screw Diameter (mm) | 90 |

| L/D Ratio | 26:1 |

| Heating Load (kW) | 22 |

| Main Motor (HP) | 30 |

| Screen Changer (HP) | 3 |

| Die Face Drive (HP) | 2 |

| Water Pump (HP) | 2 |

| Spin Dryer (HP) | 3 |

| Production (Kg/Hr.) | 100-150 |