Extruder / Extrusion

₹1,675,000.00

The new Edge-Trim has been designed specifically for use with blown film (multi-layer or mono-layer) to provide small, energy-efficient, non-obstructive recycling of edge trim. Its compact and "open" construction allows for low maintenance, non-operator-dependent, and online operation. AC vector and direct-drive technology keep energy consumption down. Plugs and sockets allow for routine maintenance to be carried out by the operator without the need to wait for dedicated maintenance personnel. An air pelletizing system is used for quick and easy access for cleaning while eliminating the problems associated with water-cooled systems.

₹2,187,000.00

Introducing our innovative screw feeder machine, a versatile solution for plastic material recycling. Our high-performance screw feeder machine is designed to handle a wide range of plastic materials, including LLDPE, LDPE, HM, HDPE, PP, HIPS, PC, BOPP, OPP, and PS. With a vented die for enhanced cooling and efficiency, as well as a precision die face cutter, it excels in transforming edge trim, film, and various plastic waste into premium-grade granules. Our force-fed extruder, equipped with a flexible screw feeder, offers reliability and efficiency, enabling you to minimize plastic waste and contribute to a sustainable future. This user-friendly machine is not only easy to operate but also simple to maintain, making it an invaluable asset for any plastic recycling operation. Whether you're seeking precise granulation or enhanced recycling capabilities, our screw feeder machine is the solution you've been looking for.

₹4,060,000.00

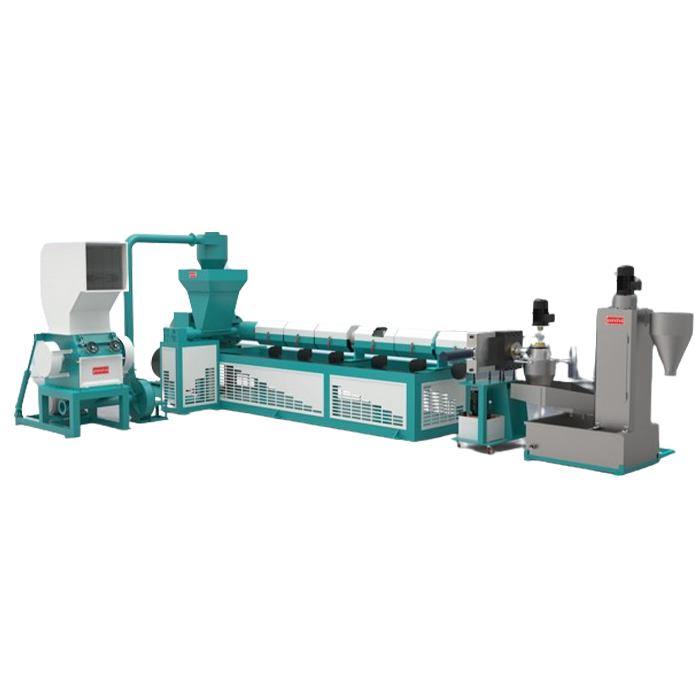

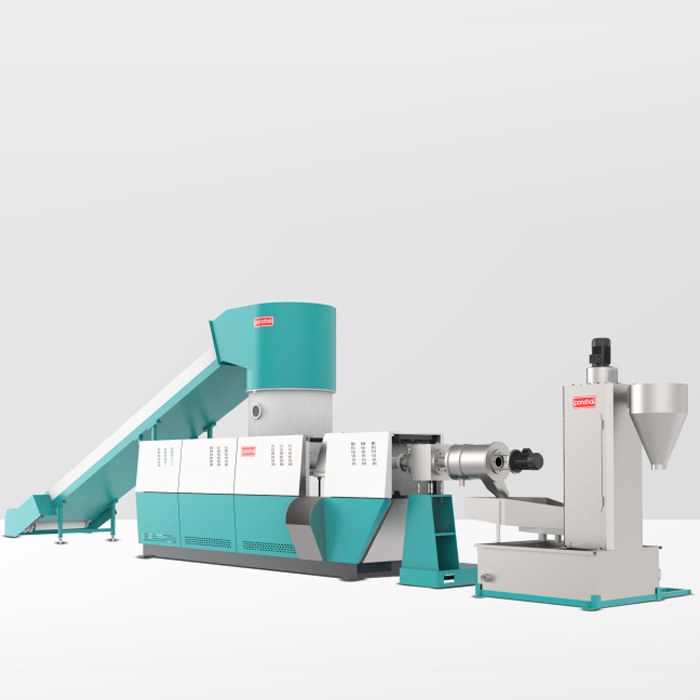

Panchal offers advanced plastic recycling plants and state-of-the-art polythene recycling facilities, representing innovative solutions for sustainable waste management. These facilities are the result of our unwavering commitment to environmental conservation and resource optimization. Our cutting-edge plastic recycling plant is designed to efficiently process a wide range of plastic waste, including in-house waste, pre-consumer waste, and post-consumer waste. This holistic approach ensures a comprehensive solution for plastic recycling. In parallel, our dedicated polythene recycling plant excels in handling polythene materials, making a significant contribution to environmental sustainability. This facility harnesses advanced technology and efficient processes to convert polythene waste into high-quality recycled products.

Both plants feature a cutter compactor (agglomerator/densifier) and an extruder, facilitating the breakdown of waste materials into smaller particles within the cutter compactor. These fragments are then conveyed to the extruder, where they undergo melting and transformation into reusable, eco-friendly products.

₹2,510,000.00

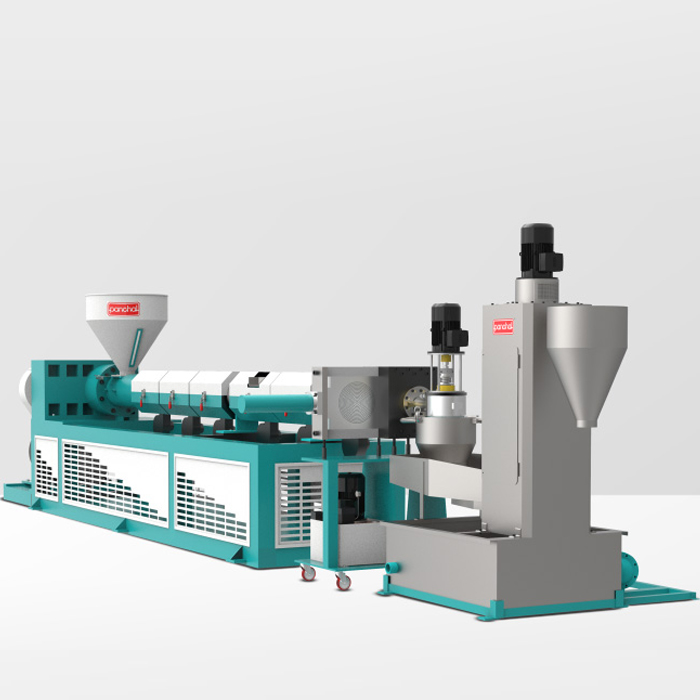

The Panchal Double Stage Extruder is a versatile machine that can be used for recycling a variety of plastic materials, including those that are highly printed or have high gas formation during reprocessing. The machine has two stages, with the first stage having a longer L/D (length to diameter) ratio than the second stage. This allows the first stage to melt the plastic more efficiently and remove any air bubbles or contaminants. The molten plastic is then transferred to the second stage, where it is further processed and extruded into granules. The Panchal Double Stage Extruder is a reliable and efficient machine that can be used for a variety of plastic recycling applications. It is ideal for use in manufacturing, packaging, and automotive industries.

₹1,920,000.00

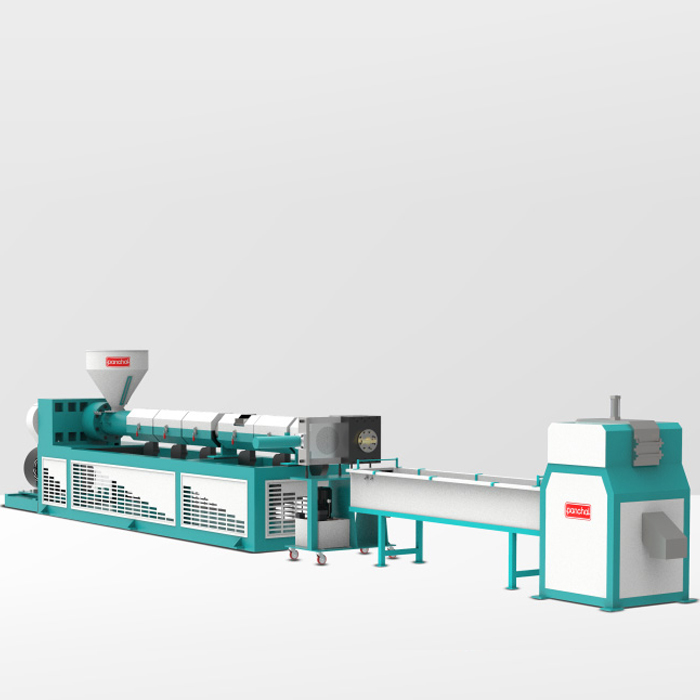

The Panchal EX-Series extruder machine with extruder machine plastic and extruder machine price considerations is a high-performance extruder machine designed for plastic granulation, recycling, and reuse. Crafted from top-notch materials, this extruder machine is built to endure. Operating and maintaining this machine is a breeze, and it excels at granulating a variety of plastic materials, including LDPE, HDPE, and PP.

₹2,120,000.00

When considering the acquisition of an extruder machine, one crucial factor to weigh is the cost. This financial aspect can significantly impact your budget and the overall feasibility of your plastic recycling and compounding operations. Our commitment to offering highly competitive prices sets us apart in the industry. The extruder machine itself is a versatile solution for efficiently processing a wide range of plastic materials, from LDPE and HDPE to HM, ABS, PS, and more. Its adaptability makes it an invaluable asset across diverse applications, including plastic recycling, compounding, and plastic machinery. Moreover, our innovative die-face cooling system, which utilizes high-pressure water jets, ensures that plastic materials do not overheat and adhere to the die. This results in a cleaner, more uniform product, streamlining plastic material processing while keeping costs in check.